One of the appealing aspects of 3D printing is the freedom the designer has in his design. But even with 3D printing there are limitations to what a 3D printer can produce. These limitations are inherent to a specific 3D printing process. In this post, I go into one of these limitations which is structural strength.

Structural strength is one of the most important limitation to recognize when designing for 3D printing. It defines if a 3D printed part can survive the different steps involved in the manufacturing of the part — from printing to cleaning until shipping.

Structural strength is also almost impossible to assess. For that reason, the structural strength is translated into a minimum wall thickness requirement / design rule. The minimum wall thickness is an approximation of a structural strength analysis, but is far easier to assess by an operator, than the structural strength itself.

Since it is an approximation of structural strength, the minimal wall thickness requirements can differ from operator to operator. Also, the print orientation of the critical areas or features of a part can impact the minimal wall thickness.

Difference between wall thickness and feature size

A wall is a structural part of the design. A feature is a protrusion or extrusion on a part which is not a structural part of the design.

A feature is any part of the design where the cross-section of the feature is smaller than the required minimum wall thickness.

Wall thickness design requirements

When I think of wall thickness, there are three distinct design requirements. I call them:

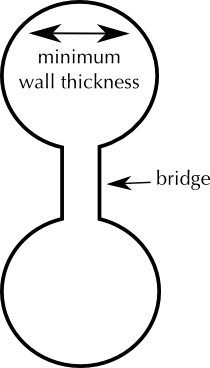

- Bridges

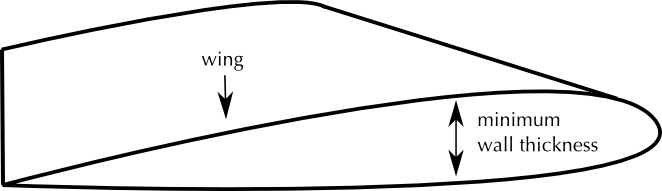

- Wings

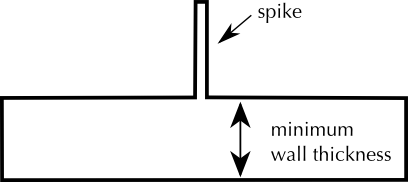

- Spikes

A bridge connects two distinct larger features of part. A great example is the neck of a figurine. The neck bridges the head and torso.

A wing is a surface area with variable thickness. Some parts of the wall are adhering to the minimum wall thickness; other parts are not. An example is a surface area, which is thick enough on one end and too thin at the other end. Like the wing of an airplane.

Spikes are lengthy protrusions starting with a base, which adheres to the minimum wall thickness, and ends with a top not adhering to the minimum wall thickness. An example are the nose hears on a mouse.

Two examples

In the image on the top, you can see that the arm of the robot has broken off. This is a bridge problem. The critical part of the design is the connection of the arm to the shoulder. The connection is too thin to provide enough strength for connecting the heavy the lower part of the arm. In this case, the part was printed, cleaned and post-finished without problems. The part broke during shipment.

The image of the bottom shows a dragon with wings. The wings are actually solid planes in the 3D design, but they can out of the printer looking like this. The solid planes of the wings were too thin to be printed correctly. This is an example of the wing problem.

Other considerations

3D printing processes with a fragile green-state are an exception to the wall thickness requirements. With those processes, the wall thickness is a dynamic variable based on the design of the part. Green-state processes use a binder during printing and have a second process step to strengthen the part. I will explore this topic in more detail in another post. Examples of green-state processes are 3DP (ZCorp, Voxeljet and derivatives) and ProMetal. Non green-state processes are SLS, DMLS, SLA, Polyjet Matrix (Objet) and FDM (Stratasys, RepRap and derivatives like Makerbot).

Another exception is a large, thin surface or plane. Even though, it adheres to the minimum wall thickness, and has the required structural strength, it can still pose a problem for the printing process. Most printing processes use heat during the production of the part. This heat is not perfectly distributed over the build-area. When a large, thin surface is unevenly heated, it will warp and bend. This is also a topic for another post.

Structural strength is an important consideration during the design of a part for 3D printing. When adhering to the minimum wall thickness requirement for a specific process or even over-engineering the critical areas, than any problems can be avoided. Since the minimum wall thickness requirement is only an approximation of the structural strength requirements, it is possible to defy the rules in certain cases. But requires export knowledge on the process and close cooperation with the operator to ensure the right location, orientation and handling of the part during the production process.

Impact of 3D printing on product design

The mono culture of 3D printing

Hyped expectations and what 3D printing really can do

Categorizing 3D printing